factory

We believe that excellent partners is the key to success in the future. Whether you are system integrators, independent software engineers, distributors or other types of technology provider, we are willing to cooperate with you, for our customers with the perfect special solution. Here is currently and we have regular cooperation of enterprises.

Optical wave communication factory

Light wave communication factory is located in the high-tech industrial zone of hengshan town, guangning county, zhaoqing city

The factory mainly produces machine cabinets and cold channel products. The first floor is divided into stamping, bending workshop, welding workshop and spraying workshop. The second floor is assembly workshop and warehouse, which can simultaneously assemble and store 700 machine cabinets.

The factory has more than 120 employees, including 13 designers and engineers, 5 quality control personnel and 8 workshop managers.

According to the current industry 4.0 trend, in order to improve the production efficiency and reduce the production cost, the company has carried out standardized design and mold making and production programming for the products to achieve fully automated production.

The factory has fully automatic spraying line and has got the environmental protection approval, which can ensure the normal production of spraying and ensure the delivery time accurately. It can be sprayed 500m in 10 hours.

Production capacity: 100-150 cabinets/day, annual shipments can reach 40,000 units.

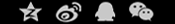

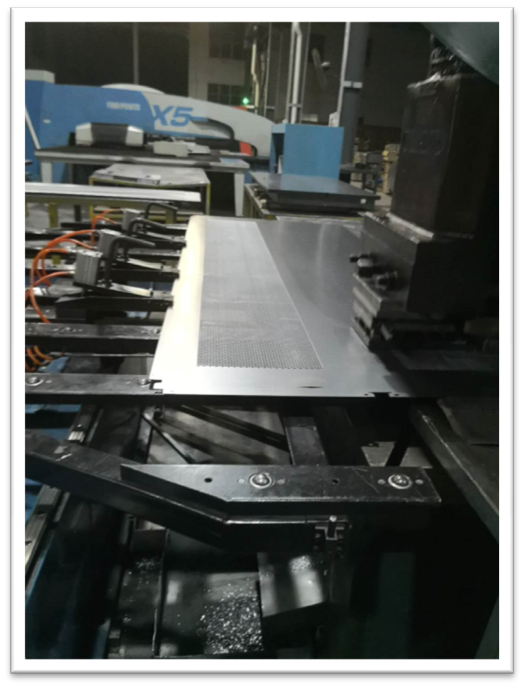

Mold production

Compared with the layout punch forming of digital punch, the standardized mold production has the following advantages:

1. Safety (fully automatic, no manual operation by employees is required)

2. High efficiency and low cost (one mold corresponds to one part, one worker takes care of several machines, automatic and rapid production)

3. Good quality (the mold is formed in one time, without several strokes of knife marks and burrs and flanges)

Fully automatic spraying line

The full length of automatic spraying line is 700 meters, and it can be sprayed 500m in 10 hours.

The company has an independent spraying line and has got the environmental protection approval, which can ensure the normal production of spraying and ensure the delivery time accurately.

Using acid pickling + phosphating pretreatment process, safe and pollution-free. Spray + immersion pretreatment, designed for IDC product structure, can handle the dead Angle in the framework. Avoid bad appearance such as orange peel and pinhole after spraying.

Powder room automatic + manual spraying, powder cyclone recovery, rapid and efficient powder, ensure efficient production. Dust-free powder spraying workshop, and equipped with air conditioning, to ensure the safety and comfortable working environment of employees.

Other equipment

In addition, the factory is also equipped with CNC punch, CNC bending machine, CNC punching machine, deep throat press, NC feeding system, fiber laser cutting machine, automatic loading and unloading system, 17 roller leveling machine and other production supporting equipment.

In order to ensure product quality (such as coating thickness, flame retardant test, salt spray test, etc.), the quality department is equipped with special quality inspection instruments, mainly salt spray test box, coating thickness detector, insulation resistance tester, combustion tester, high and low

temperature test box, pressure tester, resistance tester and other equipment.

temperature test box, pressure tester, resistance tester and other equipment.

Contact us